how to measure and calculate hardness with brinells hardness test|how to calculate brinell hardness : mail order The Brinell hardness method is a simple, fast, and reliable method for measuring the hardness of various materials. It does not require any special preparation of the test . Resultado da 1 de abr. de 2019 · Mia khalifa. 111 bin. 1 Nis 2019. 18+. Video Mia khalifa HQ Mp4. Video transkripsiyonu.

{plog:ftitle_list}

Resultado da Welcome to Buu Mal (ဘူးမယ်) အချို့ Videoများကို မမြင်ရပါက VPN လေးခံကြည့်ပေးပါခင်ဗျာ

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Harder materials will generate shallow .

Evaporation Residue Testing chain store

The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is .This ASTM standard for Brinell Hardness Testing provides detailed instructions on test specimen preparation, load application, indentation measurement, and the calculation of . The Brinell hardness method is a simple, fast, and reliable method for measuring the hardness of various materials. It does not require any special preparation of the test .

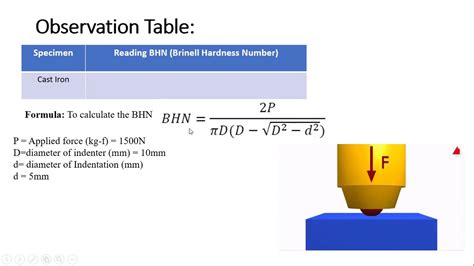

To calculate Brinell hardness using the formula, measure the diameter of the indentation (d) after performing the test and remove the indenter. Determine the applied force (F) in kilograms-force (kgf) and the diameter of the indenter .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . The HBW number is calculated from the diameter of an indentation that is made by a Brinell hardness testing machine forcing a tungsten carbide ball into the surface of the test material. The Brinell test, which is used .

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped .

The Brinell scale / b r ə ˈ n ɛ l / characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F .

Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal .This method requires optical reading of the diameter of ball indentation and using a chart to convert the average measurement to Brinell hardness value. We offer low-cost handheld Brinell scopes as well as a popular line of Automatic .The Brinell hardness test is a standardized test used for measuring the hardness of metals and other hard materials. It is performed by measuring penetration depth into a standardized material with a known hardness, typically steel or copper, when an object with a known force is pressed into it at a standard rate.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and yStandard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is applied to the surface of the material for a longer duration, typically 15 to 60 seconds. The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the hardness of light metals like lead and tin, also hard metals like steel and iron.A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.

One of the internationally accepted methods of measuring metal hardness is by Brinell testing. Brinell testing expresses the hardness numerically and the “Brinell hardness number” is a colloquial term for what is more correctly called the HBW number; that is Hardness Brinell Wolfram (Wolfram being tungsten carbide, the material of which the indenter ball (see .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.

how to calculate brinell hardness

The diameter of the indentation made on the material’s surface by a spherical indenter—typically a hardened steel ball—is used to calculate the Brinell hardness number (HB). Calculation of Brinell Hardness testing. Brinell hardness testing is used to measure the hardness of materials, particularly metals and alloys. The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the understanding of these methods are comprehensively reviewed and discussed. Basic equations and parameters .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

Brinell Hardness Test Equations, Calculators and Review . The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is measured and a Brinell hardness number is calculated from this diameter. Vickers Hardness Calculator. Hardness is a measure of the resistance of a material to plastic deformation induced by applied forces. . Another advantage of the Vickers hardness test is absence of different scales, as compared to Rockwell and Brinnell tests. At low values (VH<~400HV), Vickers hardness was shown to be the same as Brinell . https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.The diameter of the impression is the average of two readings at right angles and the use of a Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured Brinell hardness number reveals the test conditions, and looks like this, "75 HB 10/500/30" which means that a Brinell Hardness of 75 was obtained .

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . The indentation surface left behind serves as a measure of the hardness! The factor 0.102 in the equation is due to the unit “kilopond” or “kilogram-force” (1 kp ≙ 9.807 N), which was used in .

Equipment for Brinell hard- ness testing usually consists of a testing machine, which supports the test specimen and applies an indenting force to a ball in contact with the specimen, and a system for measuring the mean diameter of the indentation in accordance with the Brinell hardness test principle.The Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material's surface. . hardness and the reason so many quality assessment professionals prefer it is primarily because they can adjust the measurement load based on the material under examination .

The HRB scale typically is used for soft materials such as aluminum and brass alloys. It uses a 1/16-in. ball indenter with a 100-KG test force. Brinell Testing. Brinell testing normally is used for larger, heavy-walled pipe. Because the Brinell test is not a depth-measuring technique, it is more forgiving.Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .

(4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with . The Brinell hardness test is used to determine hardness and is done by forcing a hard steel or carbide ball indenter of a specified diameter onto the test metal surface under a specified load. This is followed by measuring the diameter .

brinell hardness to rockwell calculator

Looking for online definition of LLLL or what LLLL stands for? LLLL is listed in the World's most authoritative dictionary of abbreviations and acronyms LLLL - What does LLLL stand for?

how to measure and calculate hardness with brinells hardness test|how to calculate brinell hardness